In January of 2021, Felling’s Sales and Engineering Teams began the process of redesigning our Drop-Deck trailer toolboxes. The previous toolbox has been used since late 2016 and was set for design renew to reduce production time and increase user safety. The redesign would require some significant CAD rework, engineering took this opportunity to implement additional changes.

Benefits to the Drop Deck Toolbox Redesign

- Faster and easier production time

- Stronger, more consistent welds

- Increased water resistance

- More refined customer touchpoints

- A higher all-around quality box

Other Subsequent Toolbox Modifications:

- An improved interface between the lid and the back of the box, allowing water to shed off the top rather than draining it inside.

- Items not located by laser-cut features are located by laser-etched reference markers.

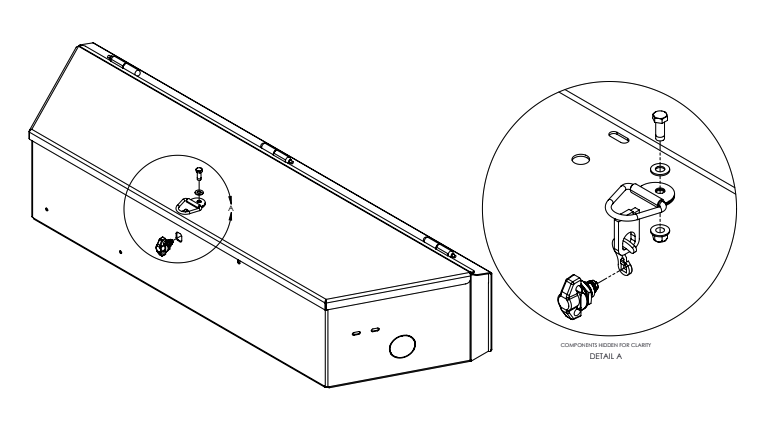

- Replacing existing hasp with a new diecast, sealed latch mechanism that is IP65 certified against water spray and can accommodate a padlock.

- A zinc-plated D-ring on the lid functioning as a handle.

The reengineered toolbox was fully released to the production floor at the beginning of October 2021. The new toolbox will be used on all Drop-Deck models including the I (Drop-Deck I), Tilt (Drop-Deck Tilt), IT-I (Industrial Tilt), Generator, and EZ-T series trailers. The toolboxes will also be used on our new Reel and Self-Loading Reel (SLR) trailers, as well as several other model lines going forward.

Contact Felling Trailers Today!

Learn more about our drop deck trailers and the new drop deck toolbox design! Contact us here, chat with us on our website, or give us a call at 1-800-245-2809.