By Mark Rapp, Felling Trailers Utility/Telecom Product Manager

When working on pole trailer specifications, there are a few items that need to be defined to set it up properly.

- Length of longest pole that will ever be transported.

- Length of the poles that will be transported primarily.

- Maximum weight carrying capacity.

- Style of Pole Trailer (Poles only or combo)

Length of Pole Trailer

There are many factors to determine how much overhang a pole can tolerate. Length isn’t the only determining factor. There are several classes for which a given length of the pole can be rated. The overall diameter at the ground line of the pole and the overall diameter at the top of the pole are the deciding factors in what class a pole will fall under. A class 1 pole is more rigid than a class 5 pole and, therefore, can tolerate more overhang. It would be up to the end-user or the pole supplier to determine how much overhang they can tolerate.

Let’s say we have an electrical cooperative whose main pole transporting concern is in the 40′ to 45′ range. A trailer designed to carry this load daily can, when necessary, haul longer poles as long as they have a higher class rating and are in good condition. Due to the extreme increase in the tail swing, a trailing vehicle may be required.

Although not perfect a good formula to follow when determining the needed overall extended length is, Extended Length x 1.6 + 3 (40′ extended x 1.6 = 64′ + 3 = 67′ pole length.) You then need to subtract the distance that is needed for clearance issues when turning. If there is only one pole loaded, this can stay at the max pole length. When additional poles are laid side by side, you have to start pulling the poles back to allow for a proper turning radius. Typically 4′ is the maximum set back that’s ever needed.

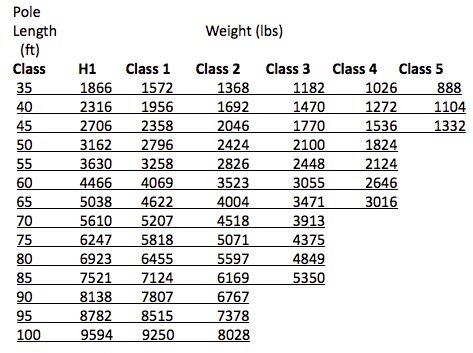

Weight of Pole Trailer

Although pole weights vary depending on the type of tree and preservative process used, they usually differ only slightly. This is a weight chart based on Southern Pine—CCA treated, which is the heaviest of the wood pole choices.

Wood poles are the most common type of utility poles used. Other types of material are available, such as wood laminate, fiberglass, and concrete.

Special care is sometimes needed for these applications. Padded and/or additional bolsters and tie-downs may be required. The rear overhang may need to be reduced as well. Unlike a wood pole that is tapered, many of these poles have a center of gravity in the center or near it.

At times, people will inquire about the pole trailer product to haul pipe lengths. This is okay as long as the material being hauled is hanging off the back, similar to a utility pole. If the material being hauled is required to be supported along its entire length, this trailer model is not recommended. The axle is set towards the rear, allowing the overhang to offset the tongue weight. Not having any or enough overhang will cause excessive tongue weight.

Want to learn more about our Utility Telecom Trailers? Felling Trailers has a full line of Utility Pole Trailers to fit your needs. Give us a call at 1-800-245-2809 or fill out this simple form, and we will contact you!